“Polybond” Resin Bonded Slabs are known for their uniform fiber distribution, lay pattern, & bulk density which contribute to excellent load bearing characteristics...

“Polybond” Building Rolls are low density insulation material made of noncombustible mineral wool fibers bonded with thermosetting resin binders...

"Polybond” Lightly Resin Bonded Mattress are characterized by the uniform distribution of fibers, fine diameter & flexibility

“Polybond” Pre-formed sectional pipe insulation is a specialized product made of chemically coated mineral fibers in specific size...

| # | Product Type | Density (Kg/m3) | Max. Service Temp (°C) | Dimensions (mm) | Finish |

|---|---|---|---|---|---|

| 1 | Polybond Resin Bonded Slab (RB Slab) | 48-200 | 750 | 1000x500, 1200x600, Thick: 25-100 | With or without Al. Foil / BGT / WGT / Alu. Glass |

| 2 | Polybond Building Roll | 48-96 | 550 | 7000x1100, 5000x1100, Thick: 25-100 | With or without Al. Foil one side |

| 3 | Polybond Lightly Resin Bonded Mattress (LRB Matt.) | 80-160 | 750 | 1640x1220, 3280x1220, 4920x1220, Thick: 25-100 | G.I / S.S Wire Mesh one or both sides |

| 4 | Polybond Sectional Pipe Insulation (SPI) | 128-160 | 750 | Len – 1000, Thick: 25-100, NB: 0.5”-16” | With or without Al. Foil one side |

| 5 | Polybond Loose Mineral Wool | - | 750 | 40 Kg / Bag | - |

Contributes to lowering greenhouse gas emissions and is recyclable.

Made from stone/slag and naturally non-combustible.

Effective in reducing external noise for buildings and cabins.

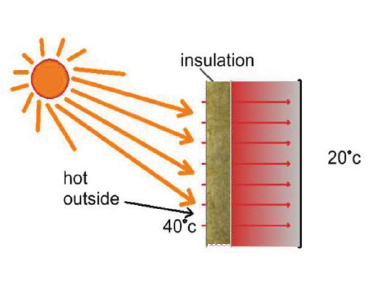

Importance of efficient thermal insulation due to increasing energy costs at high temperatures in processes and industries.

| Company | Polybond Insulation Pvt. Ltd. | Product Name | "Polybond" Mineral Wool Thermal Insulation Products |

|---|---|---|---|

| Trade Name | Engineered Mineral Fibres | Authorized By | Mr. Shailesh Kakkad (Commercial Manager) |

| 1 | Product Name | Super Fine Loose Mineral Wool, Mineral Wool Resin Bonded Slab, Mineral Wool Lightly Resin Bonded Mattress, Pre-Formed Mineral Wool Pipe Section, Mineral Wool Building Roll. | |

| 2 | Information About Product | Classification: "X" R - Phrases: Irritating to skin |

|

| 3 | Possible Hazards | The mineral fibre has been classified as irritating to skin. High dust contents may cause irritation to the throat & eyes. |

|

| 4 | First-Aid Measures | Do not rub or scratch the skin if irritation occurs. Rinse under running water using soap. If irritation occurs in eyes, do not rub. Flush eyes with water & consult physician. |

|

| 5 | Fire Fighter Measures | The product does not create any fire hazards. However, the packing material may cause fire. Fire extinguishing media like water, foam, CO2 or dry powder can be used. |

|

| 6 | Accidental Release Measures | No special measures required. Maintain space for movement between the rows while stacking material. | |

| 7 | Handling & Storage | Use hand gloves while handling material. Unpack material only at application site. Keep work area clean. Dispose of scrap material in a suitable container. Ensure good ventilation at storage space & application site. Protect material against adverse atmospheric conditions. |

|

| 8 | Personal Protection | Wear disposable face masks, suitable hand gloves & safety goggles. Wear loose fittings, long sleeved, long legged clothes. Change clothes after completion of work. |

|

| 9 | Disposal Measures | Stable non-reactive hazardous waste acceptable at landfills for non-hazardous waste. The waste material can be used in agriculture farming & domestic gardening for holding water for long periodWear loose fittings, long sleeved, long legged clothes. Change clothes after completion of work. |

|

| 10 | Transportation Information | Material should be fully covered while transporting. | |

| 11 | Good Working Practices | Please follow the “Code of practice for manufacturers & users of insulation wool” Edited by the European Insulation Manufacturers Association (EURIMA). |

|

"Polybond" Mineral Wool is made by melting basalt stones / slags blended with coke. Using highly advanced technology, the raw basalt stones / slags are melted at high temperatures, resulting in hair-fine fibers. These fibers are then bound together with thermosetting resin binder & spread uniformly on a conveyor belt.

The material has excellent thermal, acoustic insulation & fire retardant properties. It complies with the requirements of technical standard IS: 8183:93 with the following specification.

ASTM Standard also compliance.

| Sl. No. | Property | Value | Specification |

|---|---|---|---|

| 1 | Thermal Conductivity (W/mK) At Normal Temperature 100o C | 0.043 | IS: 8183 / IS:3346 |

| 2 | Maximum Service Temperature | 750o C | IS: 8183:93 |

| 3 | Short Contents (Weight %) | <15 | IS: 8183:93 |

| 4 | Rigidity | Flexible | IS: 8183:93 |

| 5 | Corrosiveness | Non-Corrosive | IS: 8183:93 |

| 6 | Water Vapour Absorption (Weight %) | < 0.1 | IS: 8183:93 |

| 7 | PH | 6-8 | IS: 8183:93 |

| 8 | Combustibility | Non-Combustible | IS: 8183 |

| 9 | Noise Reduction Coefficient | 0.09 | IS: 8225:87 |

| 10 | Moisture Content & Absorption | 2% by Weight | IS: 8183:93 |

| 11 | Chloride Content (PPM) | Max. 10 PPM | IS: 8183:93 |

| 12 | Sulphur Content (Weight %) | Max. 0.60 | IS: 8183:93 |