"Polybond" Building Roll is a high-performance insulation material made from low-density, non-combustible mineral wool fibers bonded with thermosetting resin. These rolls are factory-laminated with reinforced aluminum foil and other materials on one side for enhanced durability. This versatile, easy-to-handle material ensures energy efficiency, temperature control, and sound absorption, with long service life and options for water-repellent production. Available in various sizes and densities, with or without aluminum foil facing.

“Polybond’’ Building Roll confirming to IS 8183, ASTM C612, BS 3958 Part-5.

Thermal Services - Upto 550 Deg. C

Fire Safety Non Combustible, IS – 3144: 1992, ISO-1182, BS-476 Part-4.

Acoustical Properties – Suitable for Acoustic Insulation

| Product Type | Density (Kg/m3) | Max. Service Temp. | Dimensions (mm) | Finish |

|---|---|---|---|---|

| Polybond Building Roll | 48-96 | 550° C | Len. x Bth. 7000 x 1100 5000 x 1100 Thick. 25-100 | With or without Al. Foil one side. |

| Company | Polybond Insulation Pvt. Ltd. | Product Name | "Polybond" Mineral Wool Thermal Insulation Products |

|---|---|---|---|

| Trade Name | Engineered Mineral Fibres | Authorized By | Mr. Shailesh Kakkad (Commercial Manager) |

| 1 | Product Name | Super Fine Loose Mineral Wool, Mineral Wool Resin Bonded Slab, Mineral Wool Lightly Resin Bonded Mattress, Pre-Formed Mineral Wool Pipe Section, Mineral Wool Building Roll. | |

| 2 | Information About Product | Classification: "X" R - Phrases: Irritating to skin |

|

| 3 | Possible Hazards | The mineral fibre has been classified as irritating to

skin. High dust contents may cause irritation to the throat & eyes. |

|

| 4 | First-Aid Measures | Do not rub or scratch the skin if irritation occurs. Rinse under running water

using soap. If irritation occurs in eyes, do not rub. Flush eyes with water & consult physician. |

|

| 5 | Fire Fighter Measures | The product does not create any fire hazards. However, the packing material may

cause fire. Fire extinguishing media like water, foam, CO2 or dry powder can be used. |

|

| 6 | Accidental Release Measures | No special measures required. Maintain space for movement between the rows while stacking material. | |

| 7 | Handling & Storage | Use hand gloves while handling material. Unpack material only at application site. Keep work area clean. Dispose of scrap material in a suitable container. Ensure good ventilation at storage space & application site. Protect material against adverse atmospheric conditions. |

|

| 8 | Personal Protection | Wear disposable face masks, suitable hand gloves & safety goggles. Wear loose fittings, long sleeved, long legged clothes. Change clothes after completion of work. |

|

| 9 | Disposal Measures | Stable non-reactive hazardous waste acceptable at landfills for non-hazardous

waste. The waste material can be used in agriculture farming & domestic gardening for holding water for long periodWear loose fittings, long sleeved, long legged clothes. Change clothes after completion of work. |

|

| 10 | Transportation Information | Material should be fully covered while transporting. | |

| 11 | Good Working Practices | Please follow the “Code of practice for manufacturers & users of insulation

wool” Edited by the European Insulation Manufacturers Association (EURIMA). |

|

"Polybond" Mineral Wool is made by melting basalt stones / slags blended with coke. Using highly advanced technology, the raw basalt stones / slags are melted at high temperatures, resulting in hair-fine fibers. These fibers are then bound together with thermosetting resin binder & spread uniformly on a conveyor belt.

The material has excellent thermal, acoustic insulation & fire retardant properties. It complies with the requirements of technical standard IS: 8183:93 with the following specification.

ASTM Standard also compliance.

| Sl. No. | Property | Value | Specification |

|---|---|---|---|

| 1 | Thermal Conductivity (W/mK) At Normal Temperature 250° C. | 0.035 | IS: 8183 / IS:3346/ ASTM-C-518 |

| 2 | Maximum Service Temperature | 750o C | IS: 8183:93 |

| 3 | Short Contents (Weight %) | <15 | IS: 8183:93/ ASTM-C1335 |

| 4 | Rigidity | Flexible | IS: 8183:93 |

| 5 | Corrosiveness | Non-Corrosive | IS: 8183:93 |

| 6 | Water Vapour Absorption (Weight %) | < 1.0 | IS: 8183:93/ ASTM C-1104 |

| 7 | PH | 7-10 | IS: 8183:93 |

| 8 | Combustibility | Non-Combustible | IS: 8183/ ISO-1182, BS-476 Part-4 |

| 9 | Noise Reduction Coefficient | 0.80 to 1.0 | ASTM C423/ ISO 354 |

| 10 | Moisture Content & Absorption | 2% by Weight | IS: 8183:93 |

| 11 | Chloride Content (PPM) | Max. 20 PPM We provide max 10 ppm also as per request | IS: 8183:93 |

| 12 | Sulphur Content (Weight %) | Max. 0.20 | IS: 8183:93 |

| 13 | Fungi Resistance | Does not encourage fungi growth | ASTM-C1138 |

| 14 | Odour emission | No odour | ASTM-C1304 |

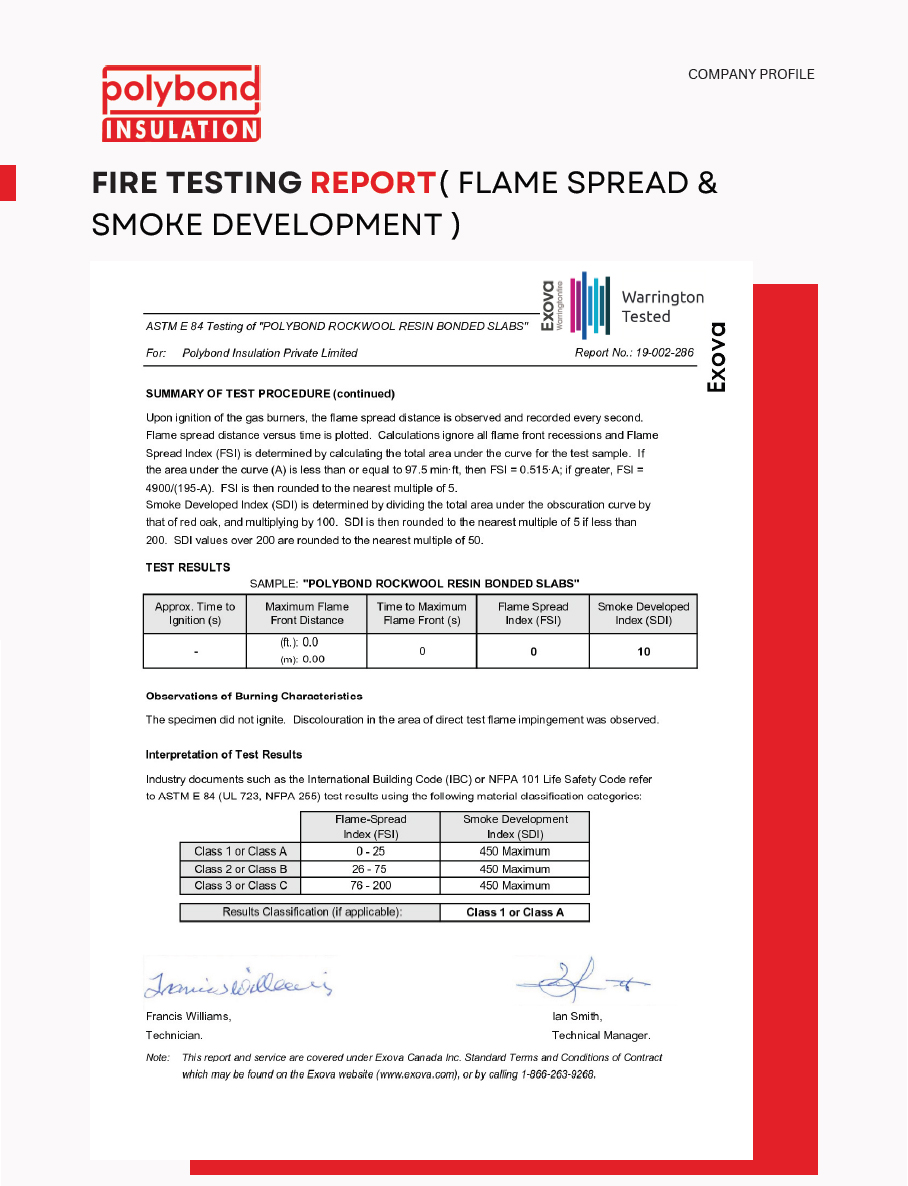

| 15 | Flame Spread Index | Class A | ASTM-E84 |

| 16 | Smoke Developed Index | Class A | ASTM-E84 |

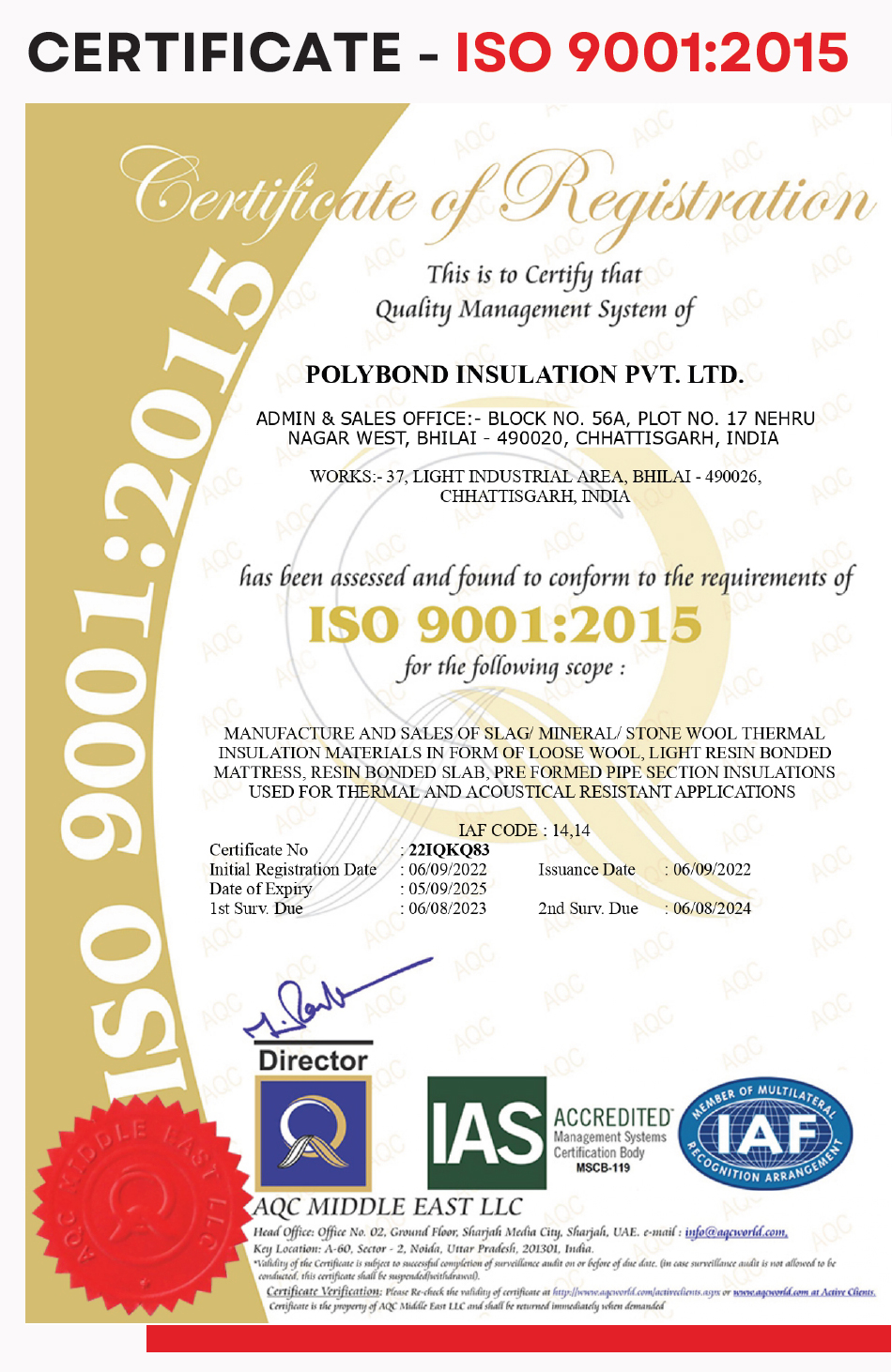

ISO 9001:2015

ISO 45001:2018

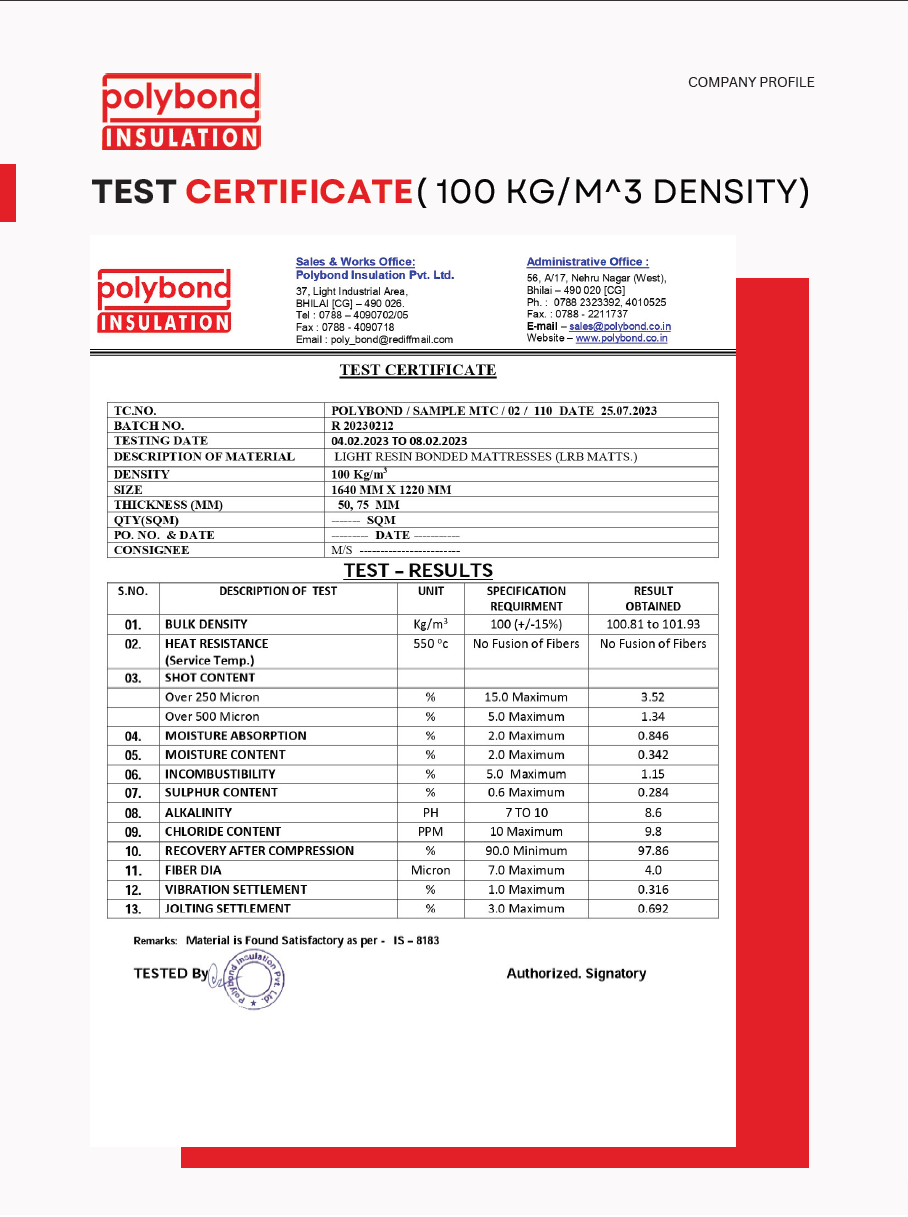

TEST CERTIFICATE( 100 KG/M^3 DENSITY)

FIRE TESTING REPORT( FLAME SPREAD & SMOKE DEVELOPMENT )

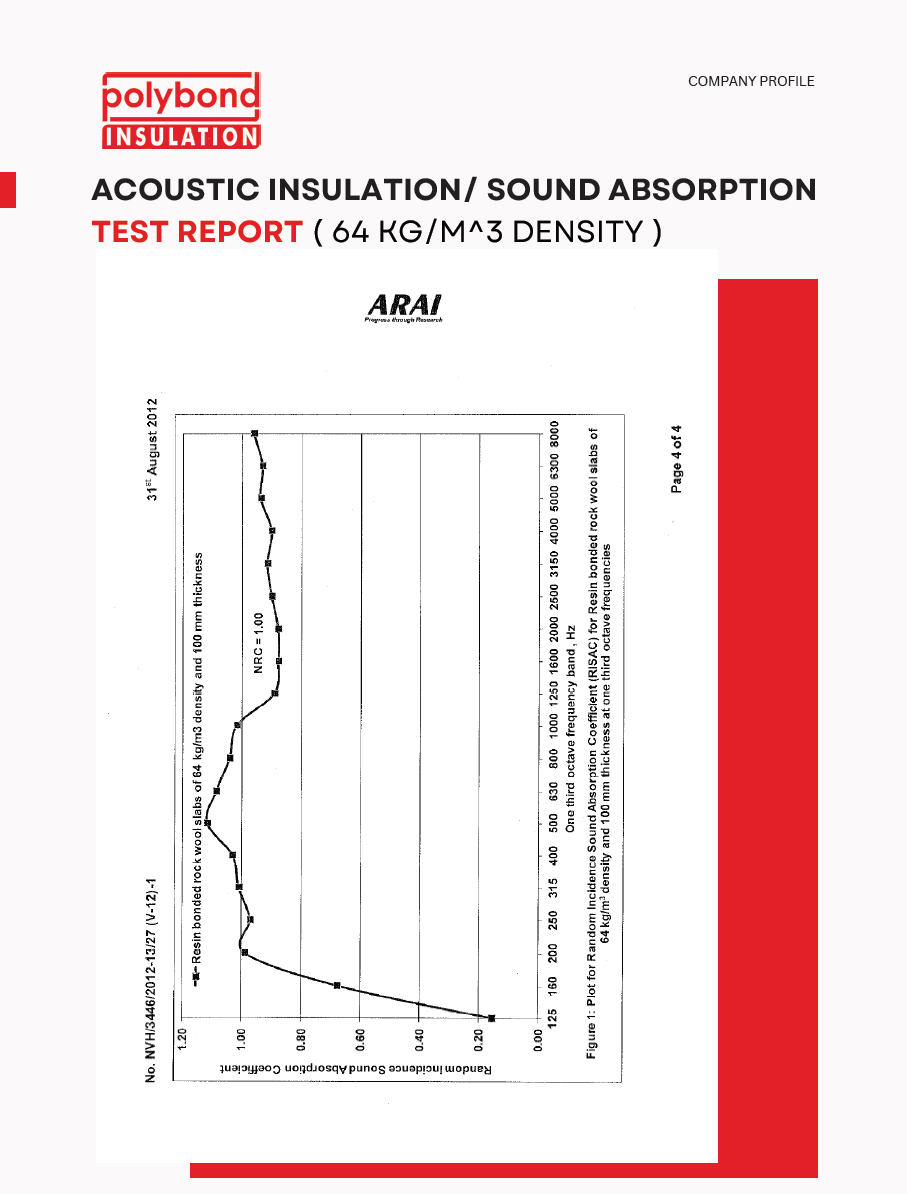

ACOUSTIC INSULATION/ SOUND ABSORPTION TEST REPORT ( 64 KG/M^3 DENSITY )

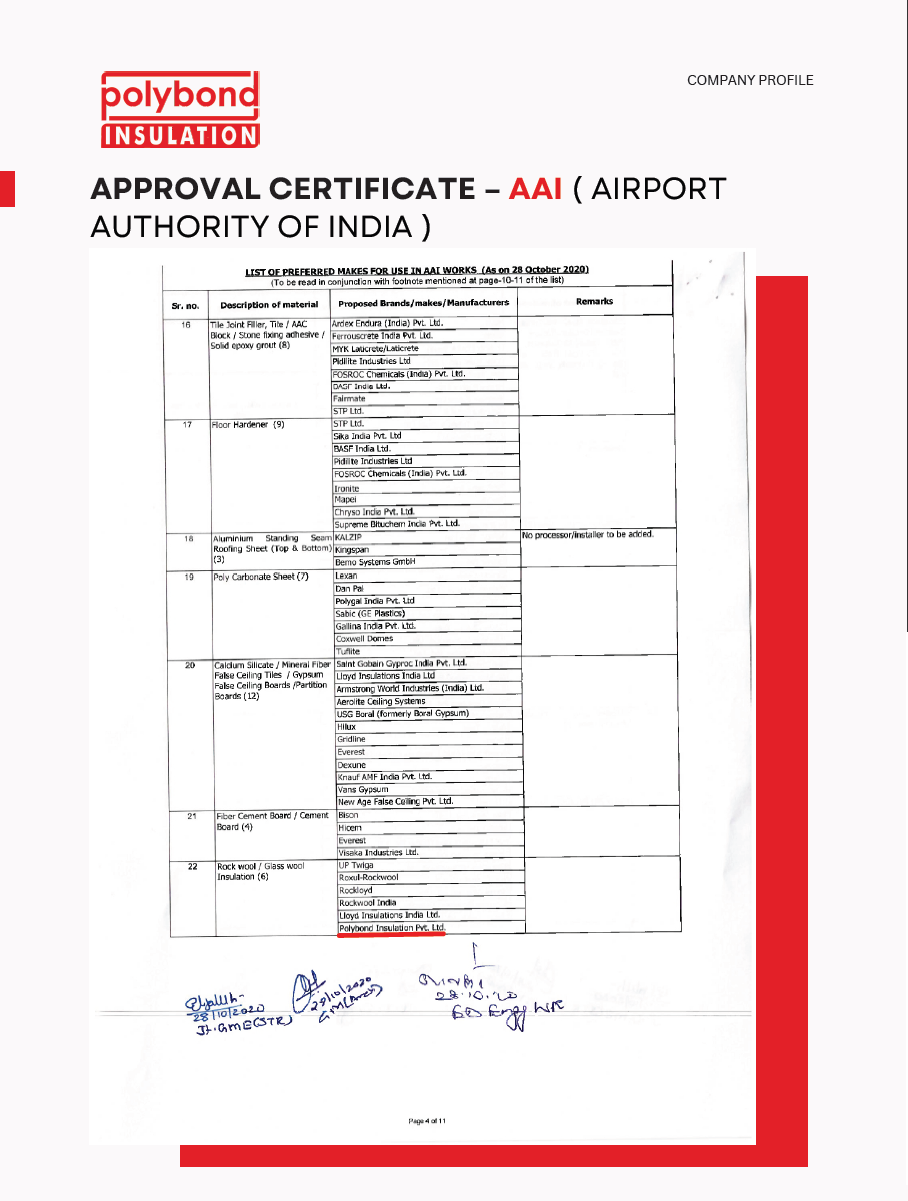

AAI (AIRPORTAUTHORITY OF INDIA)

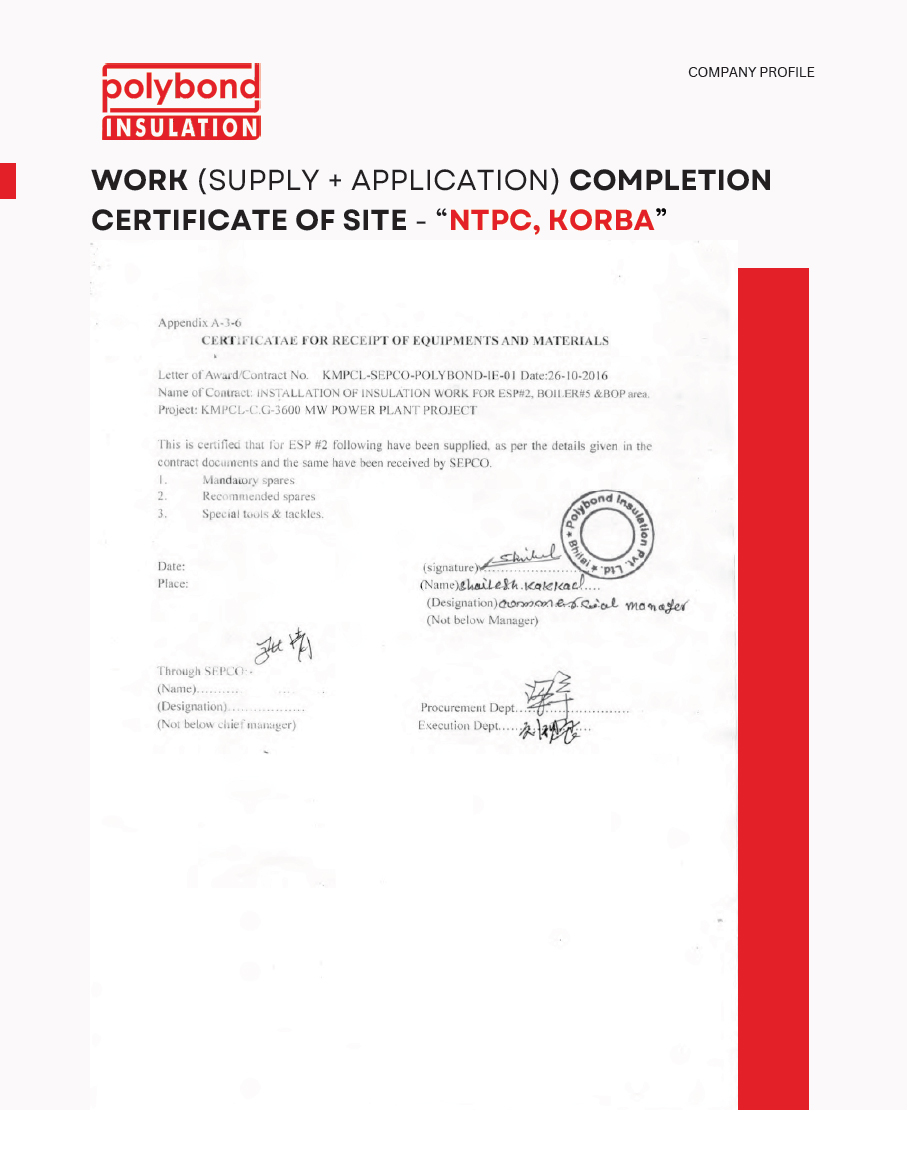

WORK (SUPPLY + APPLICATION) COMPLETIONCERTIFICATE OF SITE - “ NTPC, KORBA ”

BHEL